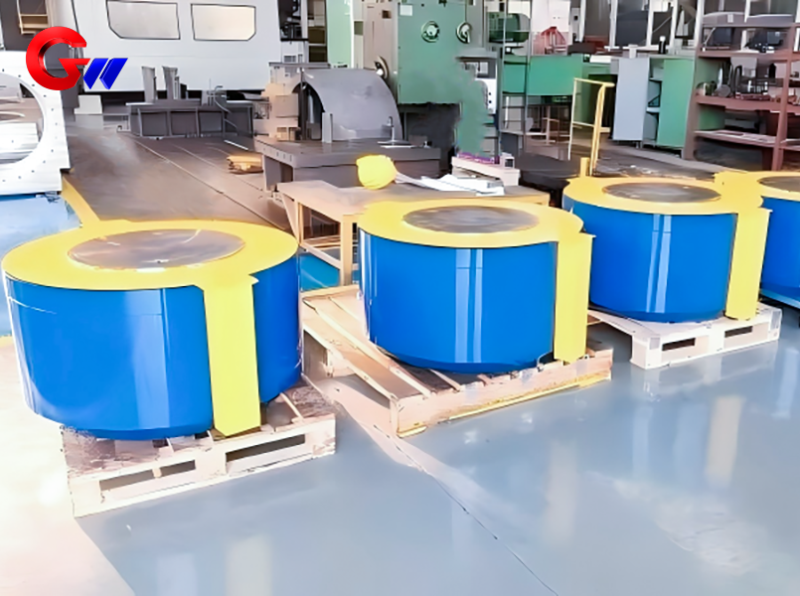

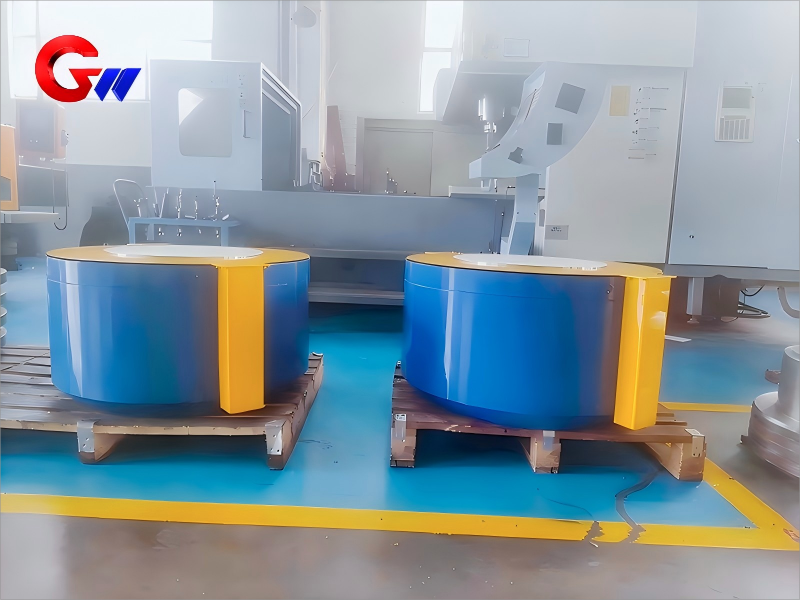

Valsverk AGV oljecylinder

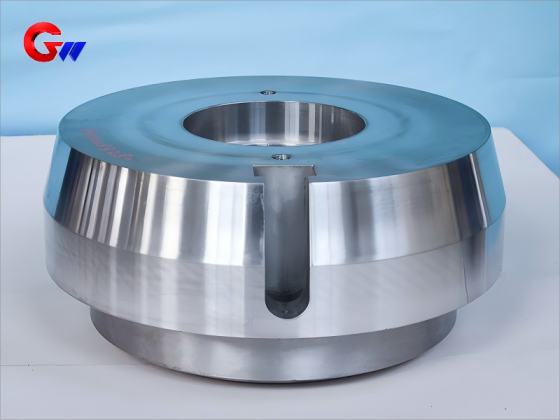

GW Precision Rolling Mill AGV-spiralcylinder är viktiga delar för högprecisionsbandverk med varm och kall bandkvarnar. Cylinderns maximala innerdiameter är 1 000 millimeter, arbetstrycket är 23 MPa, tryckmotståndstestet är 35 MPa, det interna läckaget är litet eller obefintligt, det genomsnittliga friktionsvärdet är 0,5 % eller mindre, det finns ingen krypning vid en låg hastighet på 0,5 mm/sek, och livslängden för GW Precision Rolling Mill AGV-spiralcylinder kan vara upp till cirka 5 år.

- GW Precision

- Luoyang, Kina

- Avtalsvillkor

- AGV-cylinderns årliga kapacitet är 500 stycken

- information

Rolling Mill AGV oil Cylinder

Rolling mill AGV (automatic guiding transporter) oil cylinder is a key hydraulic component for automatic material handling in the steel rolling production line,

Material Selection for Rolling Mill AGV Cylinder Application Scenario

Cylinder barrel (cylinder barrel)

Material: high-strength seamless steel pipe (such as 27SiMn, 45 # steel, 1Cr17Ni2 stainless steel).

Requirements: high compressive strength (≥ 600MPa), abrasion resistance, and finishing of inner wall (Ra ≤ 0.4 μ m).

piston rod

Material: 42CrMo, 40Cr or hard chrome plated carbon steel (surface coating thickness of 20-50 μ m).

Requirements: high fatigue strength, bending resistance, surface hardness ≥ HRC50.

Sealing element

Material: Polyurethane (PU), Buna N (NBR) or Viton (FKM), high temperature/oil resistant.

Scenario

Cylinder barrel (cylinder barrel)

Hardening and tempering treatment (quenching+high temperature tempering): improve the overall strength and toughness (such as hardness HRC28-32 of 45 # steel after hardening and tempering).

Inner surface quenching: high-frequency induction quenching, hardness HRC45-50, depth 1-2mm.

piston rod

Quench+low temperature tempering: hardness HRC50-55 after 42CrMo quenching, reducing brittleness by tempering.

Hard chromium plating on the surface: the plating thickness is 20-50 μ m, wear-resistant and anti-corrosion.

Other components

Bolt/flange: hardened and tempered to avoid stress concentration.

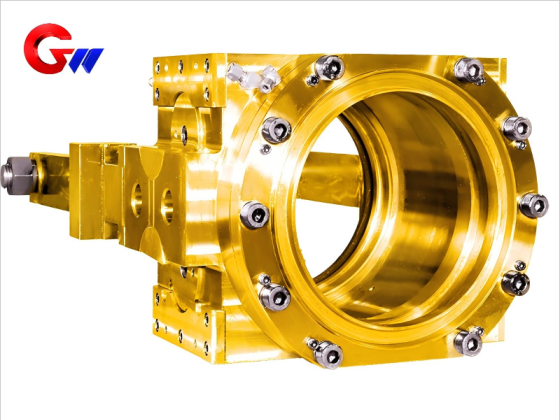

GW Precision Rolling Mill AGV Oil Cylinder Features

1. High efficiency and stability: High precision machining equipment is used to complete the precision

assembly, which realizes extremely high operating speed and stable operation under the condition of

rolling mill AGV oil Cylinder quality assurance.

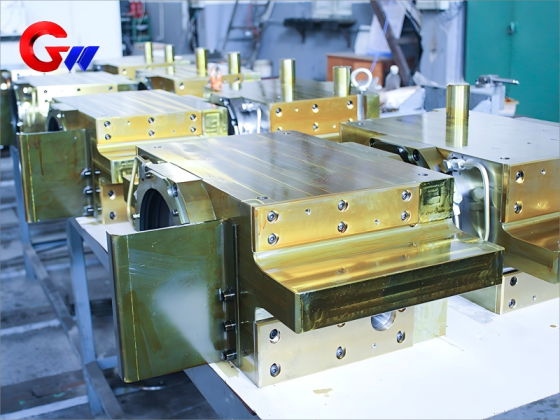

2. Durable: Adopting sturdy materials as the core structural components, and conducting strict testing

and verification, it still operates normally during heavy-duty and long-time use.

3. Easy to install and adjust: GW Precision rolling mill AGV oil Cylinder Designed according to the customer's needs with flexibility and easy to install

and debug, reducing labor costs.

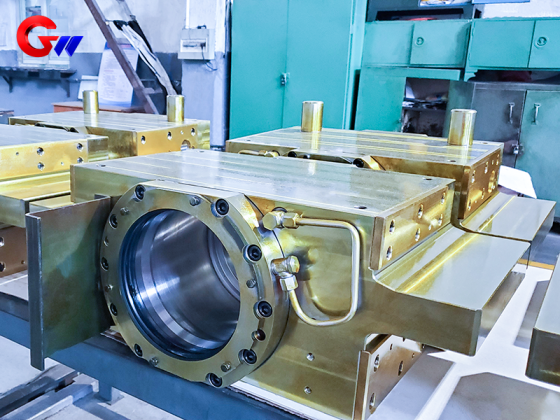

CNC machining programming

Programmers use the PC simulation processing to run rolling mill AGV oil cylinder program, optimizating processing lines and reasonable arranging the processing tools, so that the processing of the rolling mill AGV oil cylinder will be more accurate with neat and beautiful knife lines.

High-precision processing equipment

CNC vertical and horizontal machining center, five axis comprehensive machining center and other high-precision processing equipment ensure the accuracy of product processing specifications.

Quality process control

From the processing of blank, flaw detection, heat treatment to the production process, each process has inspectors to check, must be qualified before the next processing.